Khua Kling - Pak Sod is a renowned Thai restaurant celebrated for its authentic Southern Thai cuisine and fresh ingredients. Known for delivering a unique culinary experience, the brand extends its dedication to quality beyond its dishes, aiming to provide customers with a holistic brand experience. They sought custom packaging solutions that reflect their commitment to quality and distinct cultural identity, seeking a partner who could translate their brand essence into tangible products. This custom canvas bag project was part of their initiative to enhance customer engagement and expand their brand presence through high-quality, memorable merchandise.

Khua Kling - Pak Sod aimed to strengthen customer loyalty and expand its brand reach by offering distinctive, high-quality merchandise. Their goal was to deepen brand image and communicate brand values through custom-designed canvas bags that captured their unique aesthetic. For Gahumi, the objective was to showcase our production strength and OEM capabilities, proving our expertise in delivering bespoke fabric printing and sewing solutions that meet stringent client specifications for election advertising products and custom packaging. This project was a testament to our commitment to precision and client satisfaction in specialized manufacturing.

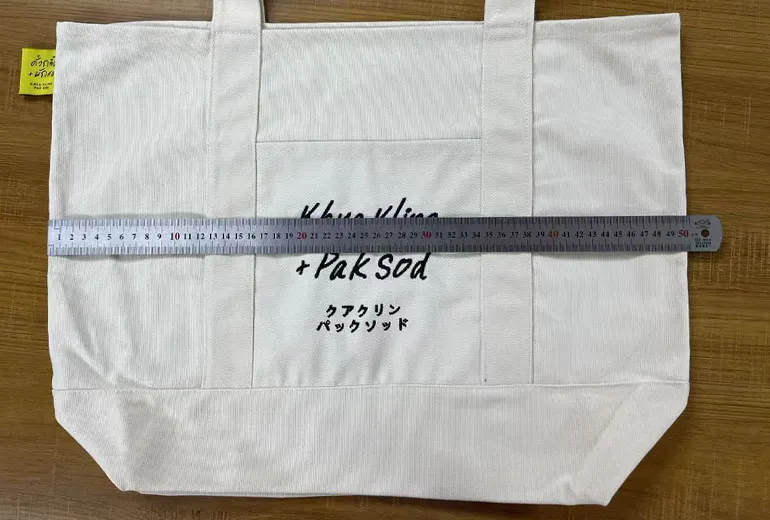

Gahumi successfully delivered all 600 custom canvas bags to Khua Kling + Pak Sod, not only meeting but exceeding expectations. The project was completed two days ahead of the scheduled 15-day deadline, showcasing our efficient production management and rapid turnaround capabilities. Both rounds of sampling passed without issues, confirming our ability to accurately translate complex designs into high-quality finished products. The bags featured impeccable stitching, perfectly aligned handles, and flawless double-sided embroidery, all packaged precisely to the client's specifications. This achievement reinforced Gahumi's reputation as a reliable OEM partner capable of handling intricate custom orders with precision and speed.

🚩About the Customer

Their recipes originate from Chumphon province, focusing on preparing classic dishes in a traditional way, reflecting the culinary heritage of southern Thailand. It's a hub for Southern Thai flavors and a family-run Thai restaurant specializing in the captivating cuisine of southern Thailand. Precious recipes passed down from their grandmother in Tha Sae District of Chumphon province inspired them to create authentic home-style dishes.

🚩About Gahumi

Founded in 1994, Gahumi is a comprehensive fabric-printing enterprise integrated with product R&D, design, manufacture and sales. We offer a full line of fabric-printing products, including towels, golf towels, flags, advertising T-shirts, sports items, fans’ scarves, hats & caps, and other election accessories, etc.

Based on 31 years of manufacturing experience, we have been exporting products to the US, Europe, East Asia, Africa, and the Middle East, and have established long-term partnerships with companies around the world.

With over 300 highly qualified employees and 3 manufacturing facilities covering a total area of 5,000 square meters (including a raw material center, sewing center, fully automatic printing center, and assembling center), our clients benefit from lower manufacturing costs and timely mass production for market launch.

The Solution

Display finished sample T - shirts of different techniques to enable customers to make intuitive comparisons.

FOR CUSTOM YOUR BRAND

Tshirt

Tshirt

Custom Hoodie & Sweat

Custom Hoodie & Sweat

Custom Bags

Custom Bags

Flag

Flag

Towel

Towel

Custom Scarf

Custom Scarf

Cap

Cap